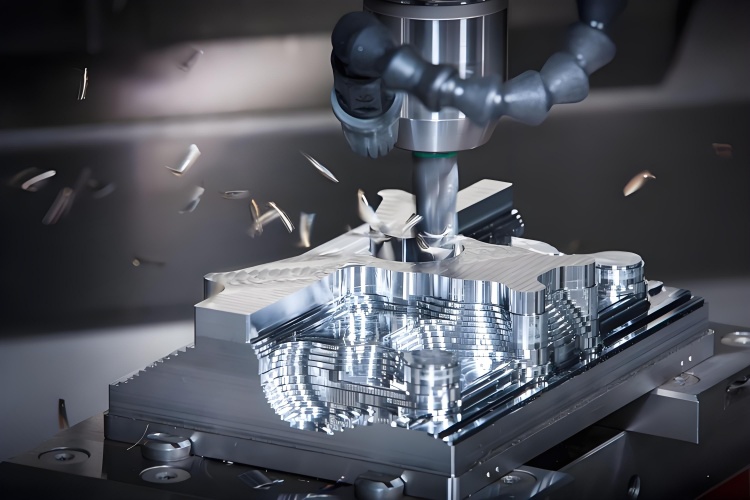

LIONSE is all about making Precision machined alloy components for industries like aerospace, automotive, medical, energy, and industrial automation.With extreme precision, exceptional durability, and outstanding performance as its core advantages, it fully meets the strict requirements under extreme working conditions. By deeply integrating CNC numerical control processing with special alloy materials, our alloy machined parts achieve micron-level dimensional accuracy, ultra-precise tolerance control, mirror-like surface quality, and impeccable mechanical stability. Even in high-temperature, high-pressure, highly corrosive, or high-frequency vibration environments, they can operate stably for a long time, providing reliable, efficient, and long-lasting solutions for customers. Whether it's core transmission parts for aircraft engines, lightweight structural components for automobiles, or precision components for medical implants, LIONSE is always driven by technological innovation and quality commitment, and is trustworthy.

We offer custom services tailored to your specific needs, from the first prototype to full-scale production. Our alloy components can handle complex shapes — from tiny parts to big structures — with incredible precision that cuts down on assembly errors and boosts overall system performance. Thanks to our precision engineering, we also cut down on material waste and rework costs, making things more cost-effective for our clients. Plus, we manage everything from start to finish — from picking the right materials to final delivery — so our parts fit perfectly into your supply chain.

|

Product Name |

Precision Machined Alloy Components |

|

Brand |

LIONSE® |

|

Certificate

|

ISO9001 |

|

Tolerance |

0.01+/- 0.005mm (Custom Available) |

We’re able to make even the most detailed shapes, like complex curves, threads, and micro-features, with high accuracy. Surface treatments like polishing, anodizing, or passivation help improve wear resistance, reduce friction, or just make things look better. Since every customer has different needs, we offer custom options.Our experienced engineers work closely with you to understand exactly what you need and deliver parts that match your specs. Whether it’s a few prototypes or a huge production run, we’ve got the skills and flexibility to handle projects of any size.

Q1: what products is your company producing?

A:For over 15 years, LIONSE® is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE® is your reliable supplier.

Q2: What is your Minimum Order Quantity and pricing?

A:The MOQ for each product is different, so it would be best to refer to the detail requirements of the product you are demanding or interested in. If you need further clarification, send me the product link and I will reply as soon as possible.

Q3:What is the production time?

A:CNC: 10~20 days.

3D printing: 2~7 days.

Molding: 3~6 weeks.

Mass production: 3~4 weeks.

Other production services: please contact with us.

Q4:How about your products' price?

A:Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.