Numerical control drilling technology features unique precision and efficiency, and is an indispensable technology in all walks of life with extremely high precision requirements.

Aerospace

In the aerospace industry, safety and reliability are beyond doubt. Manufacturers use CNC drilling technology to drill precise holes in the fuselage, engine components and landing gear of aircraft. These holes must meet extremely strict tolerance requirements to ensure the perfect fit of the components and be able to withstand huge stress and pressure.

Medical equipment

For medical devices, the biocompatibility and functionality of components depend on their precision. CNC drilling is used to manufacture bone screws, surgical instruments and implant devices. This process can create tiny, burr-free holes in materials such as titanium and stainless steel, which is crucial for the safety and success of these products.

Electronic products

The electronics industry relies on CNC drilling to manufacture printed circuit boards (PCBS). High-speed micro-drilling technology can drill thousands of tiny and precise holes on a single circuit board. In this way, from smart phones to complex computing systems, various products can achieve the flow of electrical signals and ensure their functionality and reliability.

Other precision fields

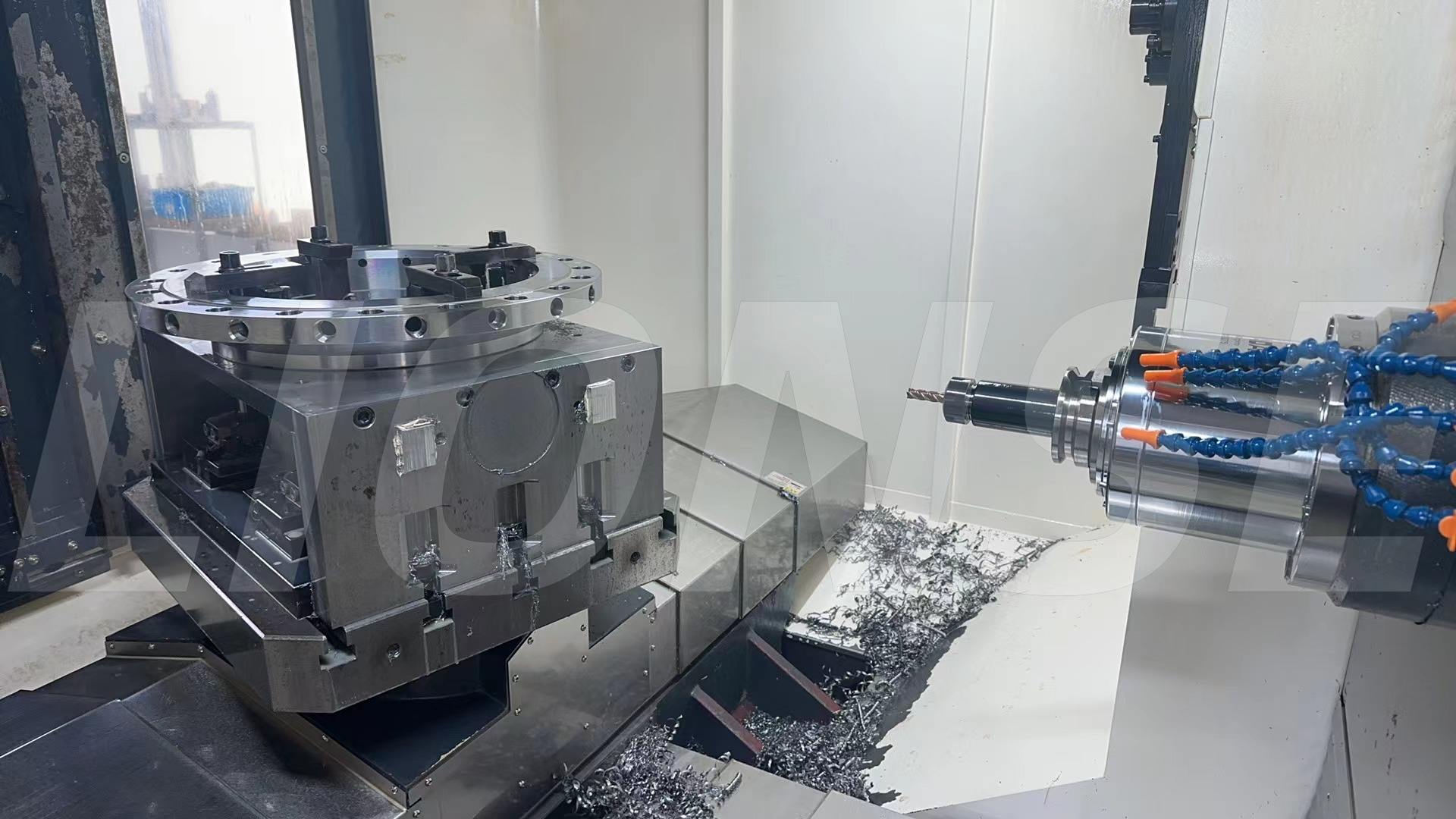

In addition to these major industries, CNC drilling technology is also very important in many other industries. In the automotive industry, CNC drilling machines are used to process engine blocks and transmission components. In the energy industry, it drills holes for turbines and oil and gas equipment. It also helps in tool and mold manufacturing to produce high-precision molds and fixtures.

If you want to know more, please feel free to contact us at any time.