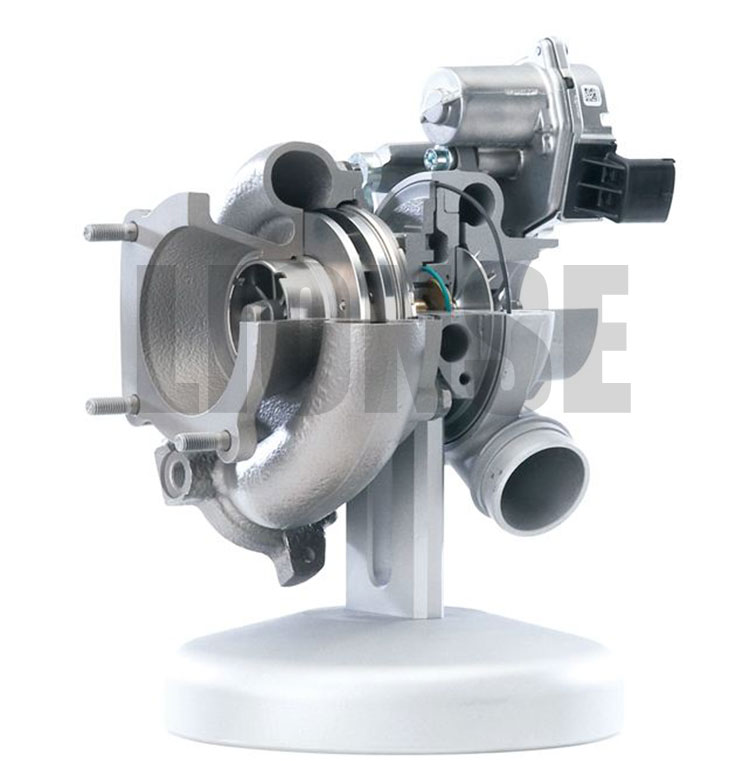

Custom Precision Turbocharger Turbine Housing by LIONSE, tailored to your specs. Custom Precision Turbocharger Turbine Housing ensures optimal airflow, peak efficiency. Engineered for reliability, delivering unmatched performance. Get yours today from LIONSE and unlock new power levels.

Our Custom Precision Turbocharger Turbine Housing is crafted from premium materials, ensuring every detail stands up to scrutiny. Designed for convenience and high performance, it features a user-friendly installation process and has undergone rigorous testing to optimize airflow and boost turbocharging efficiency, infusing your engine with boundless energy. Tailored to your specifications, it delivers exactly what you need.

|

Material

|

As Needed |

|

Surface Treatment |

Based On Customer Needs |

|

Manufacturing Processes |

Sand Casting, Precision Casting, Powder Metallurgy And Machining |

|

Service |

OEM\ODM |

|

Brand |

LIONSE |

Features:

1.Improved performance: The design of turbocharger turbine housings can optimize airflow paths and reduce airflow resistance, thereby improving the overall performance of the turbocharger. The performance of the turbocharger and wastegate assembly can be enhanced through technical means such as reducing thermal deformation.

2.Reduces thermal distortion: Advanced turbine housing design extends turbocharger life by managing heat more efficiently and reducing thermal distortion caused by high temperatures

3.Enhanced durability: The turbine housing is made of high-strength, high-temperature-resistant materials that can withstand the high temperatures and pressures generated during the turbocharger's operation, thus enhancing durability.

4.Optimize exhaust emissions: The design of the turbine housing optimizes the exhaust path and reduces the retention time of the exhaust gases inside the turbocharger, thus reducing the level of emissions.

The turbine housing of turbochargers is widely utilized in the automotive industry, particularly in high-performance and diesel-engine vehicles. In the industrial sector, it also plays a crucial role, enhancing engine efficiency and performance in industries such as shipping, power stations, and construction machinery, catering to various complex operating conditions. Additionally, it may find applications in other fields requiring high-performance engines, including aerospace and military equipment.

The turbine housing provides stable support and fixation for the turbine within the turbocharger. Through meticulous structural design, it typically comprises components such as an inlet, an outlet, a turbine chamber, and a bearing seat. Specifically, the inlet and outlet are respectively connected to the engine's exhaust system and the compressor of the turbocharger. The turbine housing is widely utilized in diesel and gasoline engines for automobiles, ships, and engineering machinery. By enhancing the intake pressure and airflow of the engine, the turbocharger significantly boosts the engine's power and torque output.

1. Q: Do you provide samples?

A: Yes, we can provide samples for you to test before mass production. But need to pay the sample fee.

2.Q: Where are your products used?

A: Our casting products can be used in automobiles, engineering machinery, valves, pumps, drainage systems, chemicals, mining machinery, machine parts, agricultural machinery, marine equipment and construction industry.

3. Q: Can you package and label according to customer's requirements?

A: Yes.

4. Q:What is the production time?

A: CNC: 10~20 days.

3D printing: 2~7 days.

Molding: 3~6 weeks.

Mass production: 3~4 weeks.

Other production services: please contact with us.