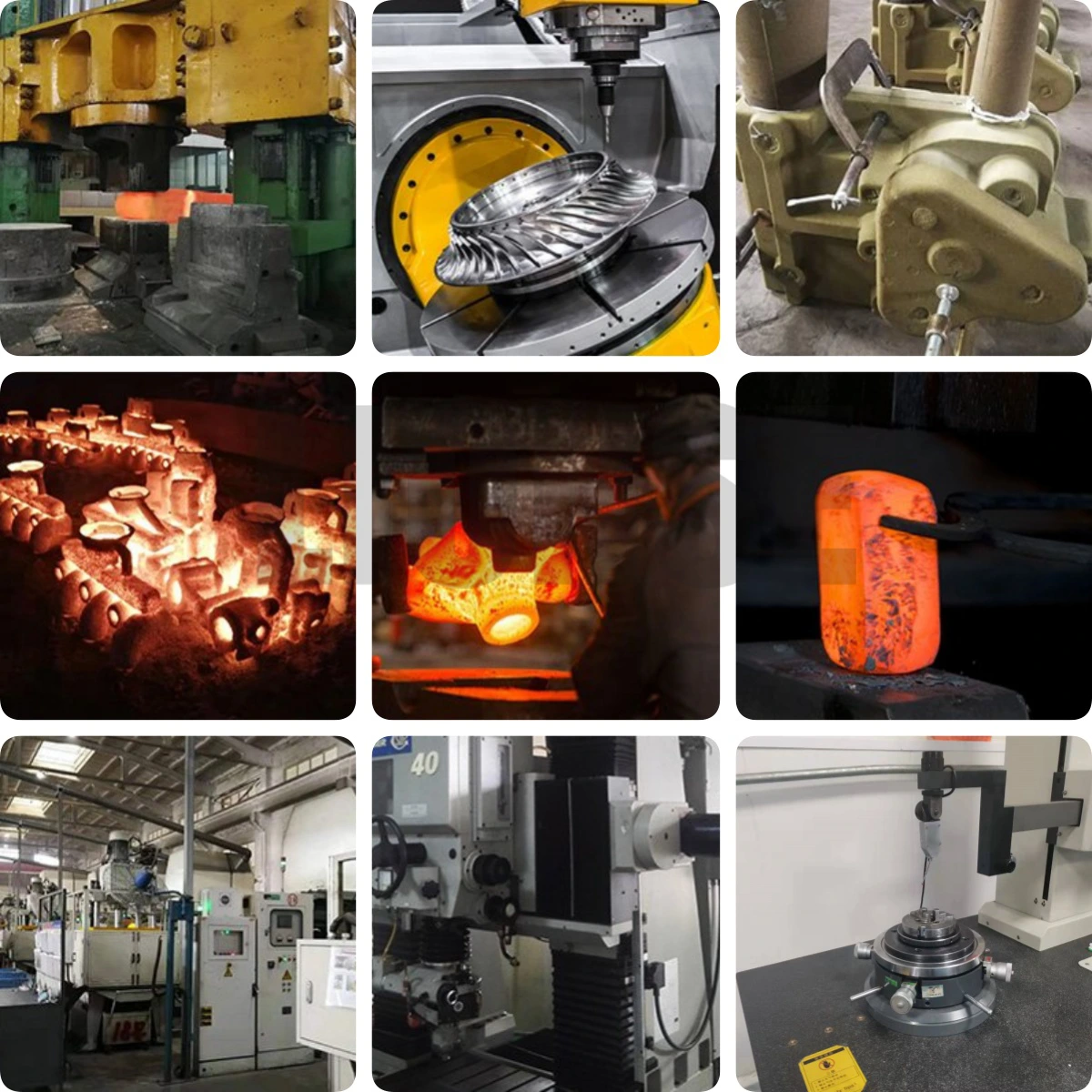

LIONSE has extensive experience in the manufacturing of CNC titanium machining parts for marine equipment for Marine Industry, which are widely used in many industries, such as automotive, aerospace, defense and art. There are many kinds of machining technology, each technology has unique characteristics and advantages. However, which method is used depends on the type of raw materials and specifications of the designed part.

CNC titanium machining parts for marine equipment are important metal parts. They may come from different machining manufacturing methods.At Lionse, we use state-of-the-art technology and techniques to produce fine Titanium Parts of Detecting Instrument parts that are capable of withstanding extreme conditions, including high temperatures and corrosive environments. We guarantee that our parts are made from the finest materials, which are carefully selected and subjected to stringent quality control checks to ensure that every part you receive is of the highest quality.

Our CNC titanium machining parts for marine equipment are produced in full accordance with the drawings and customers' requirements to ensure that they can meet your requirements.

|

MFG Process |

CNC Precision Machinining |

|

Material Capabilities |

Titanium |

|

Brand |

LIONSE |

|

Tolerance |

+/-0.01mm |

|

Origin |

China |

The following are commonmachining methods in the manufacturing industry.

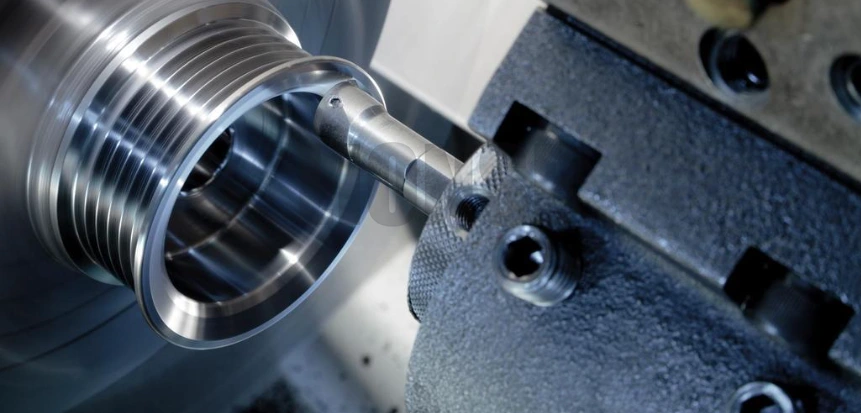

1. Turning

Turning is the process of fixing the workpiece to a rotating workpiece holding device and then using a tool to gradually cut the material on the workpiece to obtain the desired shape and size. This machining method is suitable for the manufacture of cylindrical parts such as shafts and sleeves. The method of turning and tool selection affect the shape and surface roughness of the final product.

Turning can be divided into different types, including outer circle turning, inner circle turning, surface turning, thread turning, etc

2. Milling

Milling machining cuts materials on the surface of the workpiece by rotating the tool, and by controlling the movement of the tool, it can make parts with complex shapes such as plane, concave and convex surface and gear. Milling includes plane milling, end milling, end milling, gear milling, profile milling and so on. Each method is suitable for different processing needs.

3.Drilling

Conventional drilling uses a bit with a spiral cutting edge for smaller holes and general drilling needs; Center drilling is to create a small hole on the surface of the workpiece, and then use a larger drill bit to drill to ensure that the position of the large hole is accurate; Deep hole drilling is used to process deeper holes, which requires special bit and cooling technology to ensure the accuracy and quality of the processing; Multi-axis drilling uses multiple bits at different angles to drill at the same time, which is suitable for processing multiple holes at the same time.

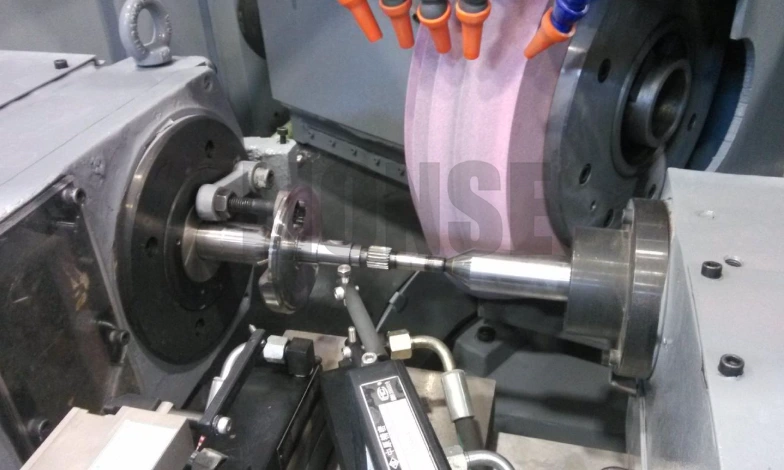

4.Grinding

Grinding is the gradual cutting or grinding away of the material on the surface of the workpiece through the use of abrasive tools to obtain the desired shape, size and surface quality. Grinding is usually used to process parts with high precision and high surface quality requirements, such as molds, precision machinery parts, tools, etc.

Grinding is divided into plane grinding, outer grinding, inner grinding, contour grinding. Surface grinding is used to process flat workpiece surfaces to obtain flat surfaces and accurate dimensions; Cylindrical grinding is used to process the cylindrical surface of the workpiece, such as shaft, pin, etc. Internal grinding is used to process the inner surface of the hole, such as the inner hole, shaft hole, etc. Contour grinding is used to process complex contour shapes, such as the cutting edges of molds and tools.

Video link:CNC Machining - YouTube

1. Product Details

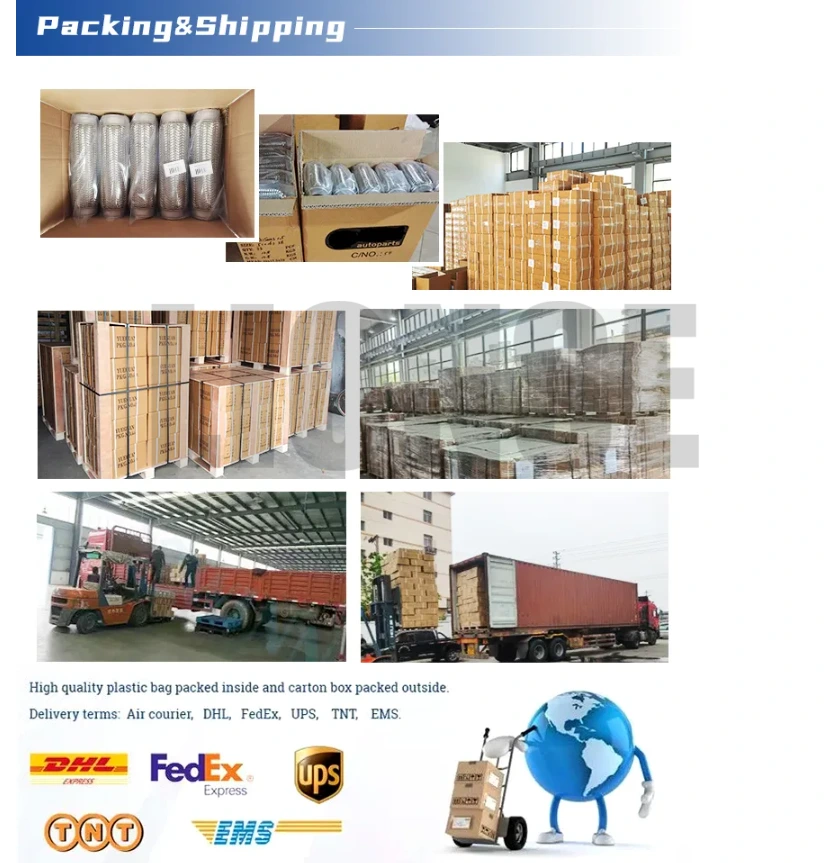

If you have any questions, LIONSE's technical sales experts are ready to help. Serving industries and businesses in North America and Europe for over 15 years, we understand the complexities of machining and the needs of your industry. Email us today to learn more and find the ideal parts for your next project.

Q1: what products is your company producing?

For over 15 years, LIONSE is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE is your reliable supplier.

Q2:How does your company control the products' quality?

Well, as we all know that quality comes first during the business with our customers we always persist in the "Quality is the life of enterprise. we are using the first confirmed cases, production inspection, and packaging seized the entire combination to control product quality strictly.

Q3:Are you a manufacturing company or a trade company?

we are a professional machining parts manufacturing company with over 10 years' of history, we have our own factory with complete produce equipment and professional engineers that we can produce out perfect products according to your requirements.

Q4:How about your products' price?

Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.

Q5.Can you do customization if I need it?