LIONSE is a leading China CNC titanium grade 5 machining parts manufacturer and supplier. With years of experience and attention to precision and quality, we are committed to providing our customers with the best Titanium Parts of Marine Equipment products. We offer competitive price and fast turnaround time, so you can get the parts you need quickly when you need them. We hope to be your partner in China.

CNC Titanium Grade 5 Machining Parts is commonly used in Aircraft/spacecraft frames and engines, Missiles and other weapons, Hydraulic system, Surveillance equipment and submarines deployed at sea, Compressor blade... At Lionse, we use state-of-the-art technology and techniques to produce fine Titanium Parts of Detecting Instrument parts that are capable of withstanding extreme conditions, including high temperatures and corrosive environments. We guarantee that our parts are made from the finest materials, which are carefully selected and subjected to stringent quality control checks to ensure that every part you receive is of the highest quality.

|

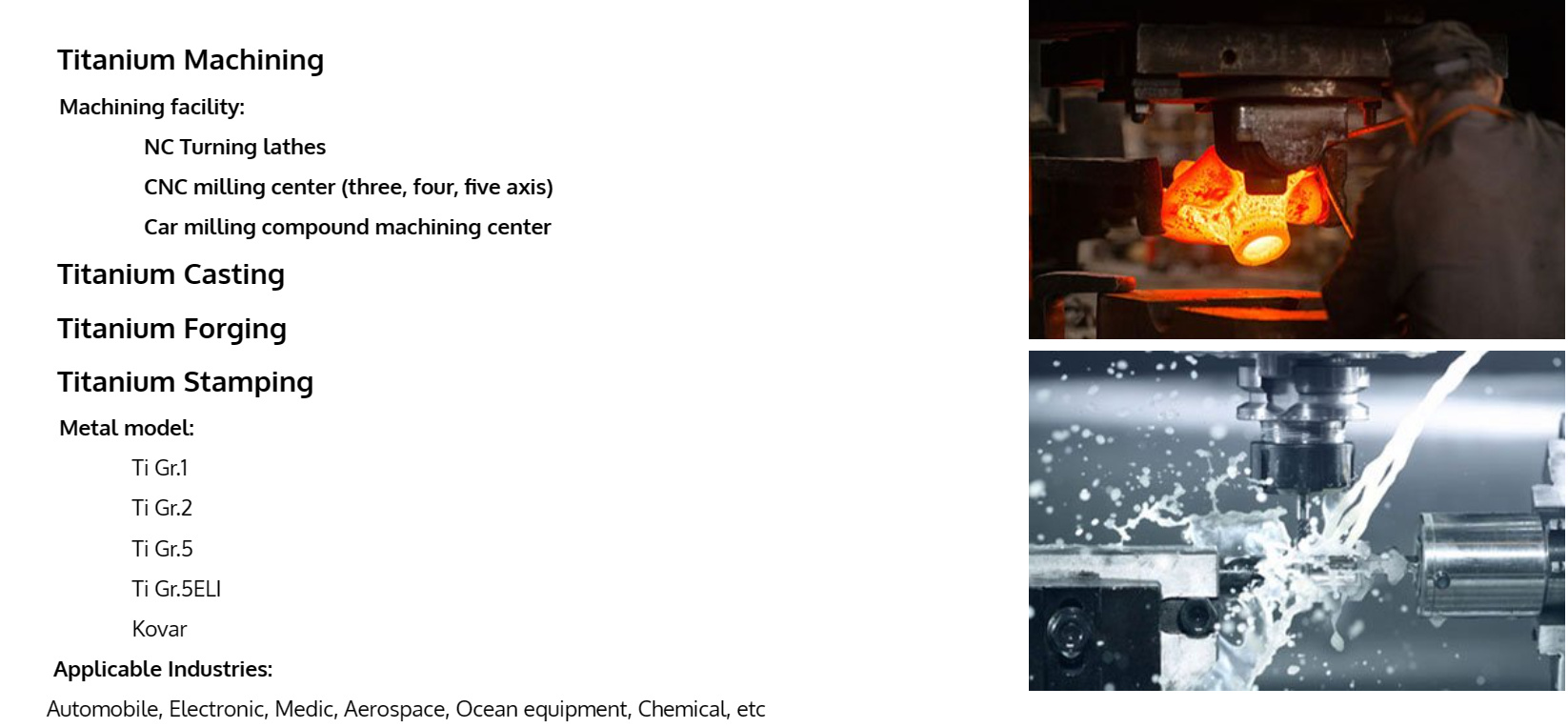

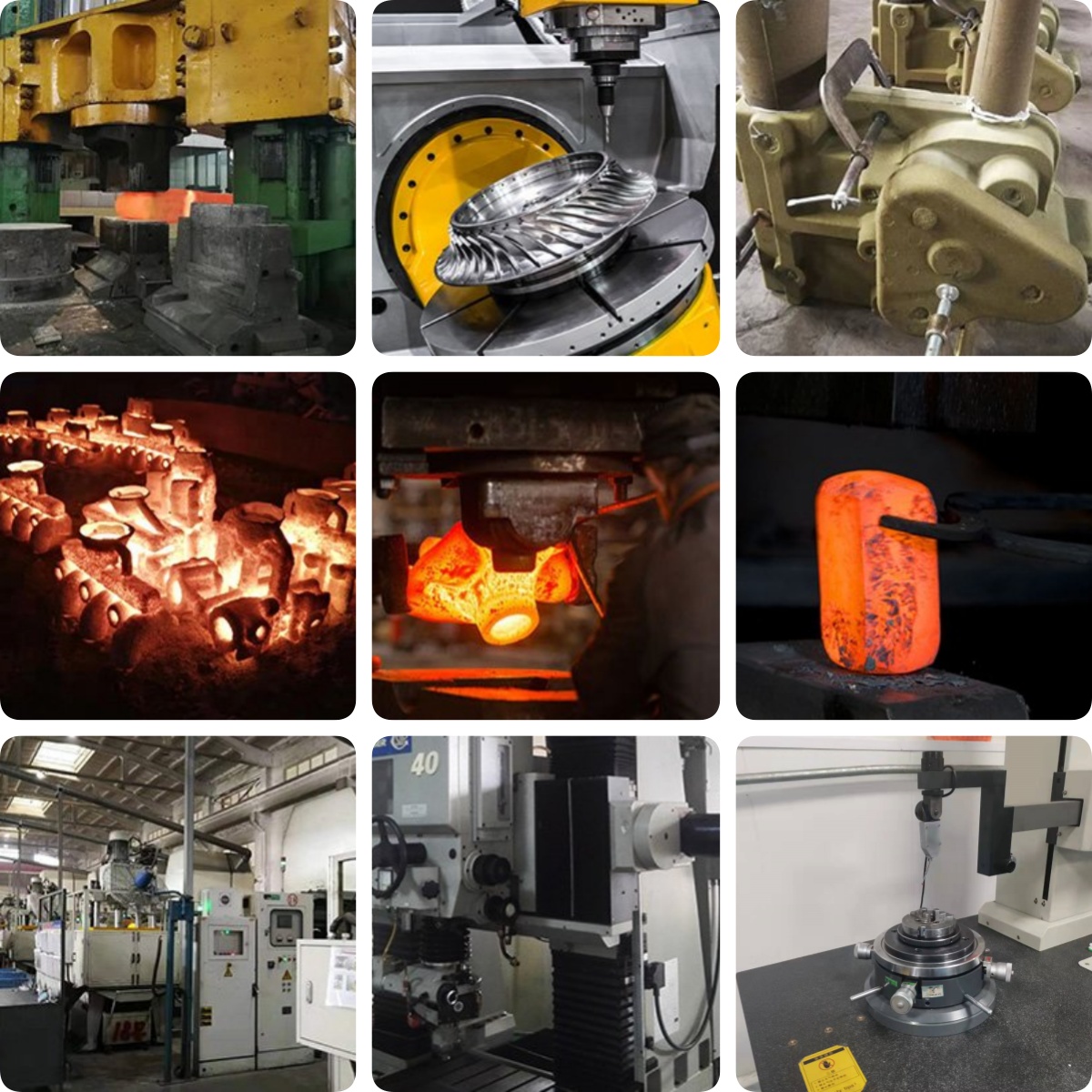

MFG Process |

CNC Precision Machinining |

|

Material Capabilities |

Titanium, titanium alloys |

|

Brand |

LIONSE |

|

Tolerance |

+/-0.01mm |

Titanium Grade 5 (also known as Ti-6Al-4V) is one of the most widely used titanium alloys, and its core advantages include:

1.High strength and light weight

Combined with high tensile strength and low density (about 4.43 g/cm³), the strength to weight ratio is significantly better than stainless steel and aluminum alloy, suitable for aerospace, automotive and high-end sports equipment lightweight needs.

2.Excellent corrosion resistance

Excellent performance in oxidizing, neutral and weakly reducing media, especially in seawater and chloride ion environment with long-term stability, suitable for Marine engineering, chemical equipment and biomedical applications.

3.Excellent high temperature resistance

It can be used for a long time at high temperature of 600℃, and has strong thermal deformation resistance. It is suitable for high temperature components such as aircraft engines and turbine blades.

4.Good low temperature toughness

It still maintains ductility and toughness at -196 ° C to -253 ° C, avoiding cold brittleness, and is an ideal material for extreme environment equipment such as deep-sea detectors and low-temperature containers.

5.Excellent biocompatibility

Non-toxic, non-magnetic, excellent compatibility with human tissue and blood, widely used in artificial joints, dental implants and other medical devices.

6.Machinability and weldability

It can be formed by forging, rolling, stretching, etc., and has good welding performance (special process is required), which is suitable for the manufacture of complex structural parts.

7.Resistance to fatigue and low thermal expansion

Strong fatigue resistance, low coefficient of thermal expansion, suitable for precision instruments and components requiring high dimensional stability.

8.Resistance to damping and heat transfer

Long vibration attenuation time, suitable for tuning fork, ultrasonic equipment, etc. Although the thermal conductivity is lower than that of copper steel, the corrosion resistance can reduce the wall thickness and improve the heat transfer efficiency.

9.Environmentally friendly and cost effective

The production process has low energy consumption, long service life, reduced maintenance costs, and the economy is better than that of traditional materials in the long run.

10.Versatility and wide application

It covers aerospace (aircraft structures, engines), medical (implants, surgical instruments), Marine (submarines, heat exchangers), energy (power generation equipment) and sports (golf clubs, bicycle racks).

If you have any questions, LIONSE's technical sales experts are ready to help. Serving industries and businesses in North America and Europe for over 15 years, we understand the complexities of casting and the needs of your industry. Email us today to learn more and find the ideal parts for your next project.

Q1: what products is your company producing?

For over 15 years, LIONSE is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE is your reliable supplier.

Q2:How does your company control the products' quality?

Well, as we all know that quality comes first during the business with our customers we always persist in the "Quality is the life of enterprise. we are using the first confirmed cases, production inspection, and packaging seized the entire combination to control product quality strictly.

Q3:Are you a manufacturing company or a trade company?

we are a professional machining parts manufacturing company with over 10 years' of history, we have our own factory with complete produce equipment and professional engineers that we can produce out perfect products according to your requirements.

Q4:How about your products' price?

Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.

Q5.Can you do customization if I need it?

Yes, we can supply customized products to meet your requirements.