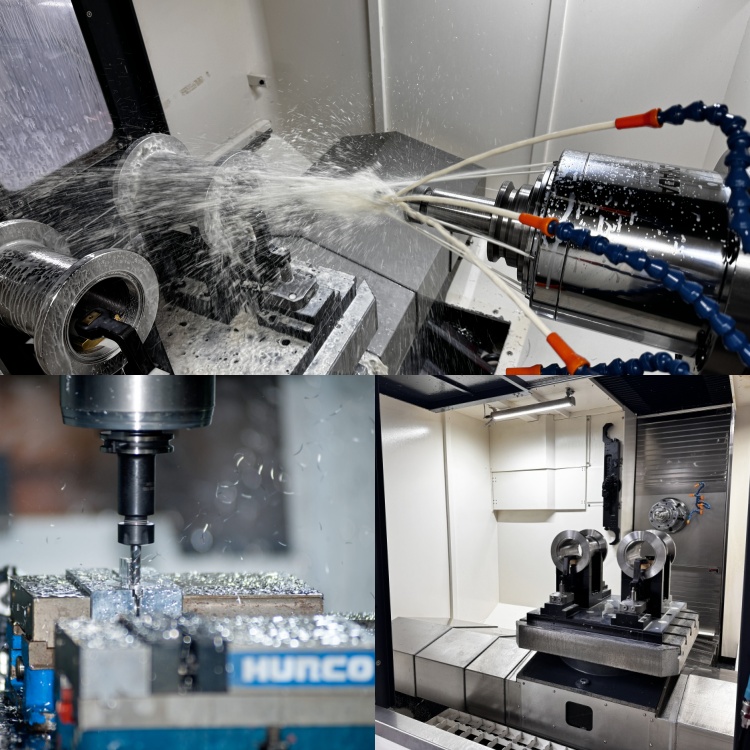

LIONSE have been in international CNC precision machining of fixture parts market for years.Our products are known for their precise and sophisticated design, crafted with the utmost attention to detail. At LIONSE, we stand behind our products with a commitment to excellence and quality. Contact us today to learn more about our CNC precision machining of fixture parts and how we can help you meet your manufacturing needs.

CNC precision machining of fixture parts are an essential part of any CNC machining job. They are used to hold the parts in place and keep the parts stable during machining. Using the right precision machining of fixture parts ensures that your parts and assemblies are properly fixed and precisely machined. We leverage our state-of-the-art machining technology to manufacture parts with tight tolerances and exacting specifications.

|

MFG Process |

CNC Precision Machinining |

|

Material Capabilities |

Aluminum,Brass,Copper,Stainless Steel,Titanium Alloys,Hardened metals |

|

Brand |

LIONSE |

|

Tolerance |

+/-0.01mm |

In CNC machining, a fixture is a process device used to quickly fix the parts during machining, so that the machine, tool and parts can maintain the correct relative position. Fixture is an indispensable part in CNC machining. Driven by the development of machine tool technology to high speed, high efficiency, precision, compound, intelligent and environmental protection, fixture technology is developing in the direction of high precision, high efficiency, modularization, combination, universality and economy. There are also many kinds of CNC precision machining of fixture parts, such as welding jigs, inspection fixture parts, assembly fixture parts, machine fixture parts, etc.

Our CNC precision machining of fixture parts are made using the highest quality materials and rigorous manufacturing processes. We have the expertise to produce customized measuring instrument parts that meet your unique requirements. We work with you to identify your needs and develop a customized solution that meets your exact specifications.

FAQ

Q1: what products is your company producing?

A:For over 15 years, LIONSE is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE is your reliable supplier.

Q2: What is your Minimum Order Quantity and pricing?

A:The MOQ for each product is different, so it would be best to refer to the detail requirements of the product you are demanding or interested in. If you need further clarification, send me the product link and I will reply as soon as possible.

Q3:What is the production time?

A:CNC: 10~20 days.

3D printing: 2~7 days.

Molding: 3~6 weeks.

Mass production: 3~4 weeks.

Other production services: please contact with us.

Q4:How about your products' price?

A:Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.