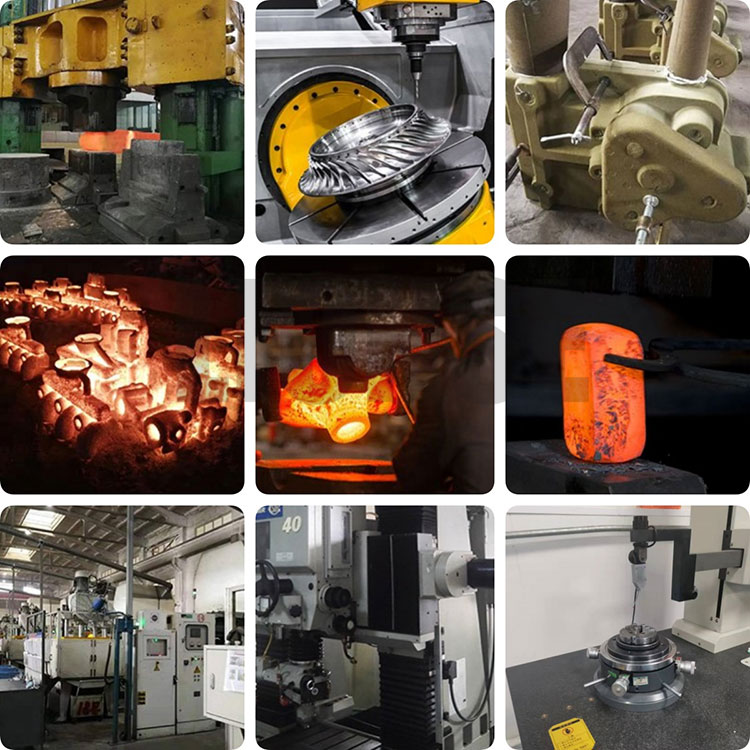

LIONSE has extensive experience in the manufacturing of Casting parts for Automobile Industry, which are widely used in many industries, such as automotive, aerospace, defense and art. There are many kinds of casting technology, each technology has unique characteristics and advantages; Sand casting, die casting and investment casting are a few of them. However, which method is used depends on the type of raw materials and specifications of the designed part.

Cast parts in automobiles are important metal parts. They may come from different casting manufacturing methods. There are five popular ways we can get car castings. They are die casting, investment casting, centrifugal casting, shell casting and continuous casting. Note that steel is the main material used in these methods, followed by aluminum.

The die casting method can produce complex shapes with high precision. Investment casting, on the other hand, is ideal for complex designs. Centrifugal casting is mainly suitable for hollow parts, and shell casting is suitable for large parts. Finally, continuous casting is suitable for elongated parts. All of these casting methods ensure versatility in the fabrication of steel components.

Our Casting parts for Automobile Industry are produced in full accordance with the drawings and customers' requirements to ensure that they can meet your requirements

The following are common casting methods in the manufacturing industry.

1. Sand casting

Product advantage

● The mold manufacturing and casting process is simple, and the tool cost is very low.

● Sand casting is compatible with almost all alloys, including ferrous and non-ferrous metals.

● Flexible shape and size. Parts weighing more than 200 tons can be cast.

● Although the dimensional accuracy is low, the post-processing is simple and takes less time.

Applications: pistons, bushings, electronic components, valves, bearings, engine crankcases, factory machinery, etc.

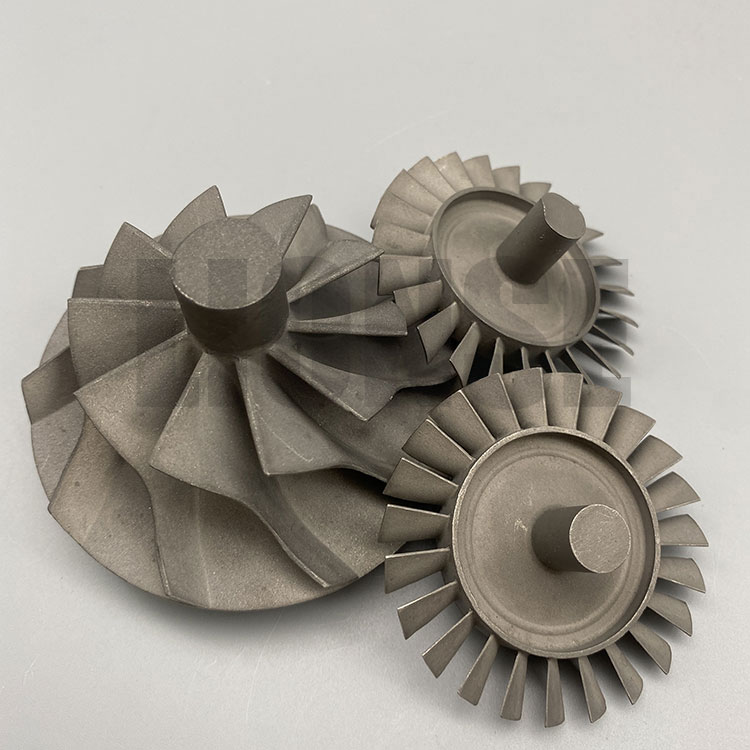

2. Precision casting

Product advantage

● Hollow sections, bottom cuts and internal channels can be made using wax molds without inserting a core.

● Fine grain structure and better surface finish.

● High dimensional accuracy (±0.1mm)

● Thin-walled parts with complex geometry

Applications: Military and aircraft components, such as engine parts, industrial equipment components, automotive engines and exhaust systems, medical implants and instruments.

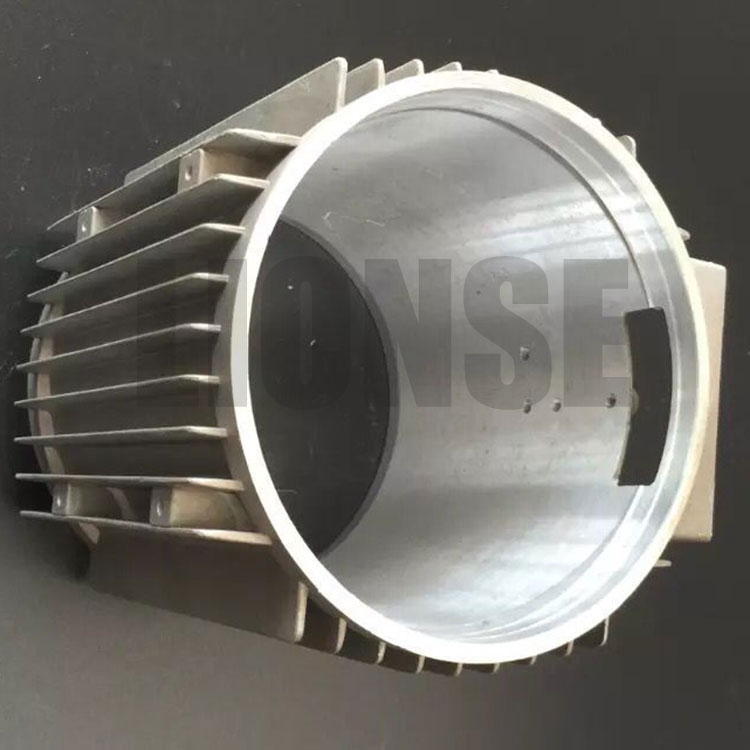

3. Die casting

Product advantage

● Strict tolerances and consistency throughout the production cycle

● The requirements for post-processing operations are low

● Mass production is cost-effective

Applications: It is used in a wide range of applications, such as automotive parts, aircraft turbine blades and fuselages, electrical housings, industrial products, machine tools and household appliances.

4. Centrifugal casting

Product advantage

● Due to the continuous supply of liquid metal, there are no pores

● Because the centrifugal cast parts solidify inward, the risk of cavitation and shrinkage is minimal.

● Since there is no riser, material consumption in the pouring stage is reduced.

● Dense and uniform grain structure.

Application: This casting manufacturing is mainly used to make symmetrical items, such as hollow cylinders, bushings, pipes, pressure vessels, disc shapes, etc.

5. Extrusion die casting

Product advantage

● Excellent surface texture and minimal porosity.

● The production cycle is fast.

● Extrusion casting can produce precise (close to final shape) parts.

● Rapid heat transfer during the pressing process results in fine microstructure.

Applications: High-strength automotive parts (such as chassis and engine mounts), aerospace parts, industrial gears and hydraulic parts, medical equipment parts, etc.

If you have any questions, LIONSE's technical sales experts are ready to help. Serving industries and businesses in North America and Europe for over 15 years, we understand the complexities of machining and the needs of your industry. Email us today to learn more and find the ideal parts for your next project.

Q1: what products is your company producing?

For over 15 years, LIONSE is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE is your reliable supplier.

Q2:How does your company control the products' quality?

Well, as we all know that quality comes first during the business with our customers we always persist in the "Quality is the life of enterprise. we are using the first confirmed cases, production inspection, and packaging seized the entire combination to control product quality strictly.

Q3:Are you a manufacturing company or a trade company?

we are a professional machining parts manufacturing company with over 10 years' of history, we have our own factory with complete produce equipment and professional engineers that we can produce out perfect products according to your requirements.

Q4:How about your products' price?

Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.

Q5.Can you do customization if I need it?

Yes, we can supply customized products tomeet your requirements.