LIONSE is a professional manufacturer of Aluminium Machining Circular Ring Die with High Productivity. We are proud to be a leading manufacturer of granulator ring dies. With years of industry experience and professional knowledge, we have become a trusted brand, providing high-quality products to our esteemed customers around the world. Our customizable options ensure that customers can customize their molds to achieve the highest efficiency and the best results. Furthermore, with competitive prices and a focus on providing the highest quality, we ensure that our customers obtain the maximum investment value.

Product Introduction

LIONSE is committed to providing Aluminium Machining Circular Ring Die with High Productivity that meets a wide range of requirements from particle size to production capacity. Our customizable options ensure that customers can customize their molds to achieve the highest efficiency and the best results. Furthermore, with competitive prices and a focus on providing the highest quality, we ensure that our customers obtain the maximum investment value.

Product Parameter

Our Aluminium Machining Circular Ring Die with High Productivity are produced in full accordance with the drawings and customers' requirements to ensure that they can meet your requirements.

Product Name

Aluminium Machining Circular Ring Die with High Productivity

Material

Customized

Processing

CNC Machining

Origin

China

Transport Package

Cartons and Wooden Cases

Length

Customized

Brand

LIONSE®

Product Details

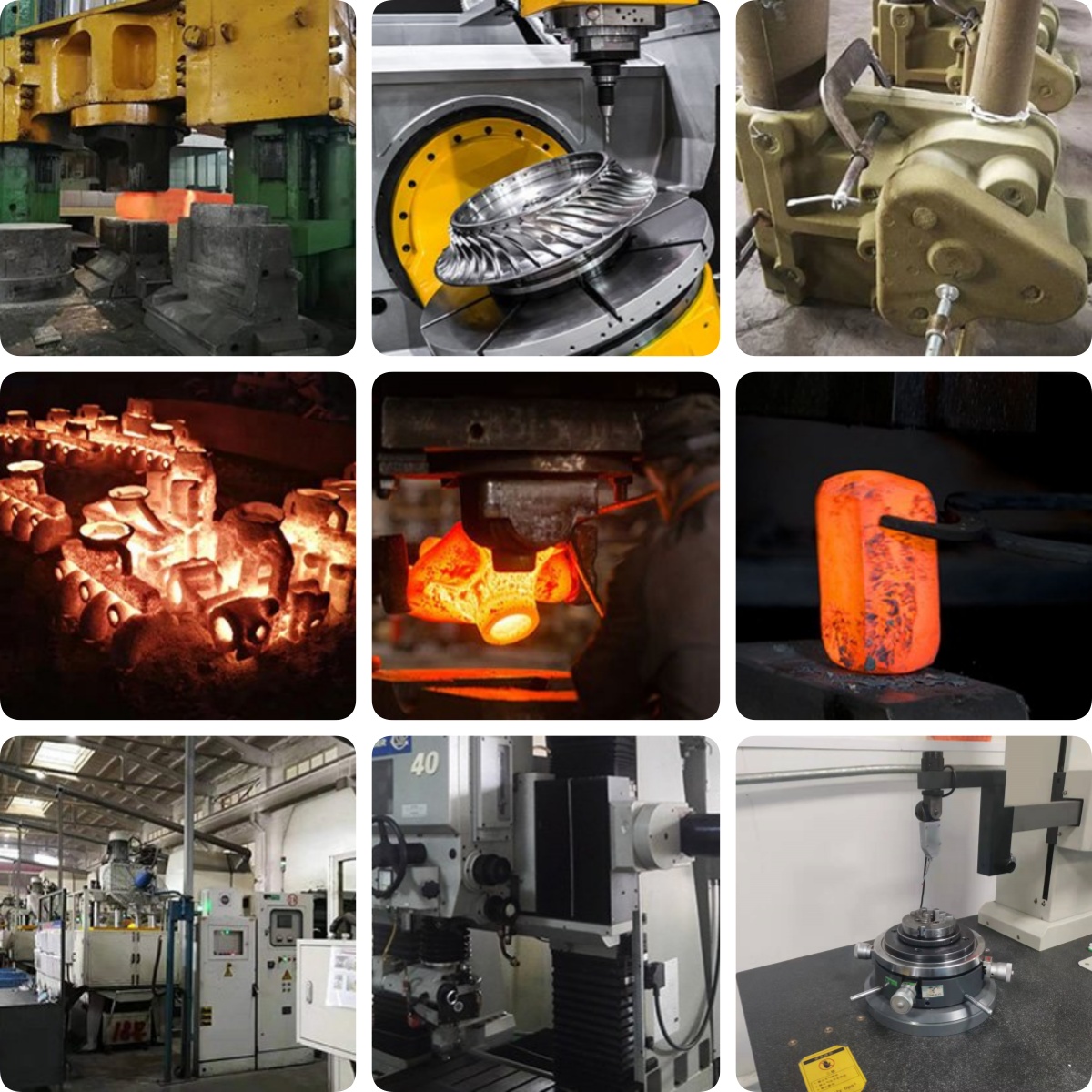

Our Aluminium Machining Circular Ring Die with High Productivity is processed through forging, cutting, drilling, heat treatment and other techniques. Through strict production management and quality systems, the hardness, uniformity of die holes and surface finish of the produced ring dies have all reached a very high quality.

LIONSE has established a well-deserved reputation in the CNC machining industry for quality, reliability, cost-effectiveness and timely delivery. To meet your expectations for aerospace processing projects, our team of mechanics and engineers will work closely together throughout all stages of product development, from prototype to production. We recognize that each project and its application are unique, so we offer each customer a distinctive yet practical solution, including precision machining services and custom surface treatments. Contact us today and let us start creating your high-quality aerospace processing parts.

Q1: what products is your company producing?

For over 15 years, LIONSE is a worldwide supplier in the distribution of titanium products, metal working and bearings. The industries we serve is including surgical implants & tools, automotive parts, chemical devices, power generation, mine equipments, aircraft, pumps etc. LIONSE is your reliable supplier.

Q2:How does your company control the products' quality?

Well, as we all know that quality comes first during the business with our customers we always persist in the "Quality is the life of enterprise. we are using the first confirmed cases, production inspection, and packaging seized the entire combination to control product quality strictly.

Q3:Are you a manufacturing company or a trade company?

we are a professional machining parts manufacturing company with over 10 years' of history, we have our own factory with complete produce equipment and professional engineers that we can produce out perfect products according to your requirements.

Q4:How about your products' price?

Well, we are insisting on the "win-win" principle. With the most advantageous price, to help our clients to gain more market share, so as to win more business.

Q5.Can you do customization if I need it?

Yes, we can supply customized products to meet your requirements.